Inside Powder River: Proudly Produced in the USA Since 1938

At Powder River, we’ve been producing livestock handling equipment in the USA since 1938. From the original cattle squeeze chute to the latest innovations in gates, panels, and working systems, every product starts as raw steel and is transformed through a hands-on process that includes laser cutting, welding, powder coating, and rigorous field testing at our manufacturing plant in Provo, Utah. We collaborate with real ranchers to design smarter, safer equipment that works with animal behavior, not against it.

Over the years, we’ve heard the stories of gates that stopped a charging bull, of chutes still in use after four decades, of ranchers hanging their first panel as kids. That’s what drives us to keep producing in the USA: unmatched durability, practical design, and a commitment to serve the people who feed this country.

Precision Cutting & Bending

It all starts with raw American steel stored on-site thats ready to be cut, bend, and built on demand. Next, the steel moves into our cutting and forming area. Using advanced CNC lasers and saws, we cut each piece to spec. Skilled machine operators then bend the steel into the shapes that become the backbone of our equipment.

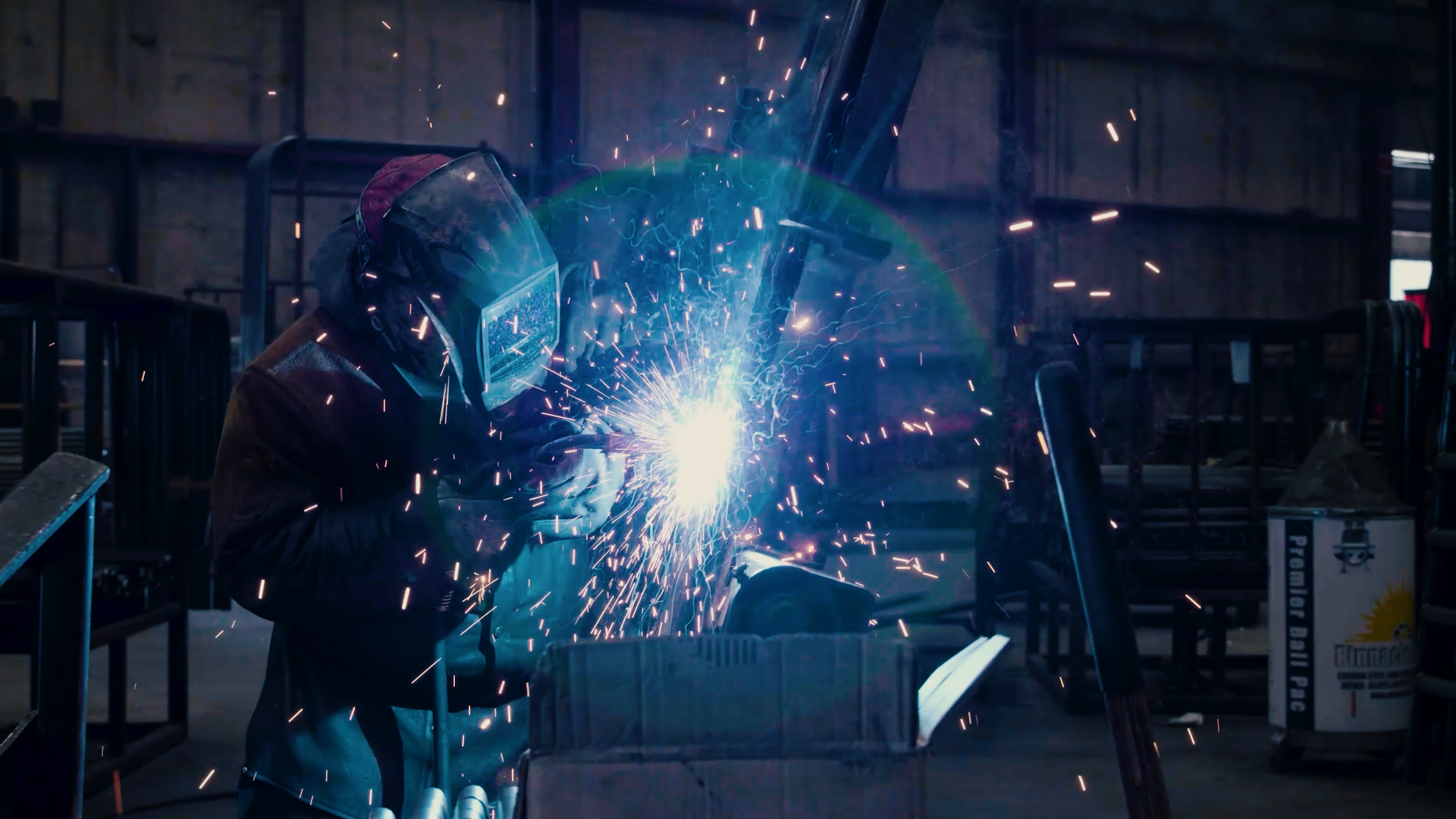

Welding & Fabrication

The cut parts head to our weld shop, where they’re either kitted or placed in our weld lines. Our experienced fabricators assemble everything from gates to squeeze chutes with strength and precision. Every weld is carefully inspected to ensure structural integrity.

Powder Coating Line

Once welded, products enter our powder coating process. First, they’re washed and dried in a high-temp oven. Then, using both robotic and human eyes, we coat every square inch in durable powder paint. Static electricity ensures even adhesion, and then it’s off to the curing oven to seal the deal.

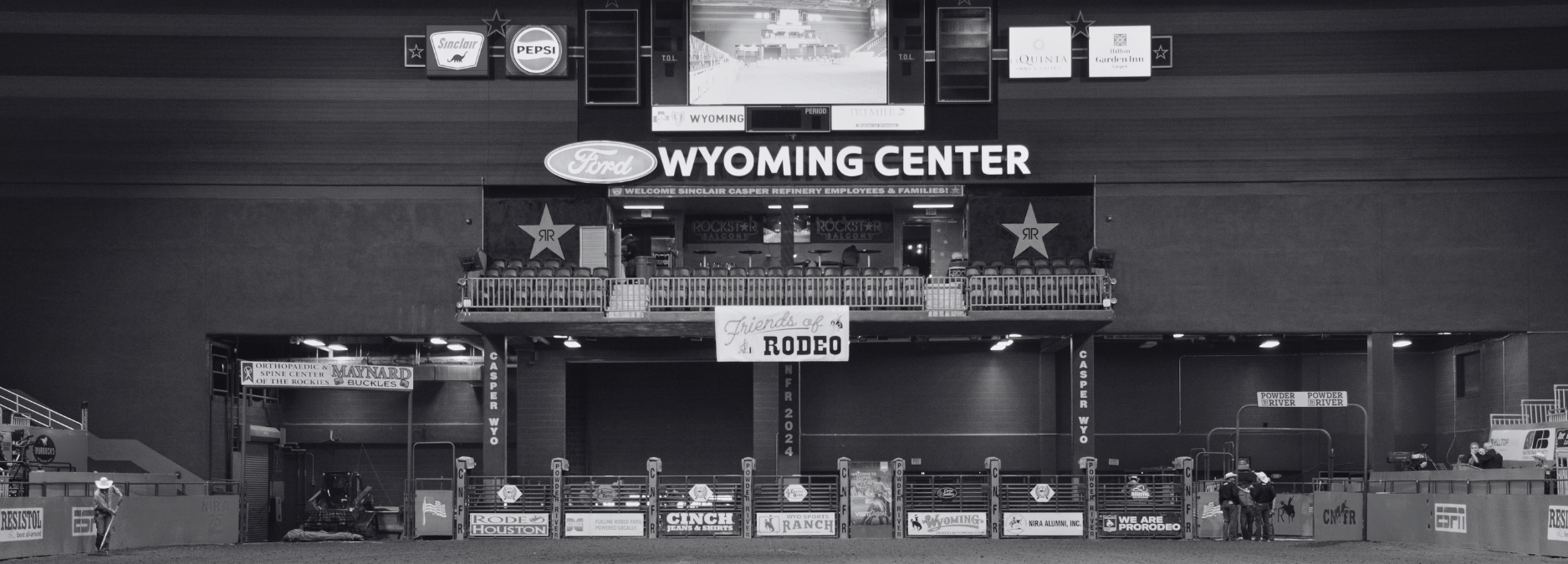

Finishing Touches & Shipping

Some products, like gates and panels, are ready to be loaded and shipped. Others, like chutes and custom rodeo gear, go through a final assembly line. Here, we add hardware like caps, pins, and accessories to make each unit ready for the ranch. Finished equipment is moved to our product yard or packaging department, then loaded onto trucks bound for dealers and ranches across the country. From beginning to end, the entire process stays under our roof.